The use of the word packaging sustainability has increased gradually over the past couple of decades. As individuals, packaging companies and governments seek ways to minimize their impact on the planet, Life Cycle Assessment emerges as a powerful packaging instrument. In this guide, we dive into the core elements of LCA, highlighting its importance, key packaging phrases and how it empowers decision-makers to contribute to a more sustainable packaging future.

Life Cycle Assessment Definition

Life Cycle Assessment for packaging is a complex method used to evaluate the environmental impacts of a packaging product throughout its entire life cycle from manufacturing, transportation, usages, raw material extraction and to end-of-life disposal. LCA is more than an environmental analysis. It is a complete journey that evaluates the ecological footprint of products and services from the beginning to the end. This guide aims to demystify LCA, providing insights into its significance and offering a clear framework for measuring environmental impacts.

Why is the LCA important?

In today’s current market, the frequency “greenwashing” poses a challenger for consumers to observe environmentally friendly products. Here’s where LCA comes in, offering a clear and scientific method for companies to monitor their environmental footprint and empowering consumers to make informed decisions.

LCA analysis dives into the environmental impact of diverse production processes, finding the most negative aspects and furnishing essential data to mitigate or offset these impacts. Beyond more assessments, LCA becomes a critical tool, trying to forward the development of more environmentally efficient processes and products.

LCA serves as a useful tool to assist in making greener decisions among various departments, including Product Development and Supply Chain. Through LCA, you gain a nuanced understanding of the ecological footprint associated with packaging, enabling you to identify areas of improvement and implement sustainable practices in manufacturing such as packaging design and logistics.

Key Elements of LCA

Understanding the key elements of LCA is essential. In LCA for packaging, there are multiple key elements that are often used. Here are some examples.

- Greenhouse Gas (GHG) Emissions

- Fossil Fuel Use

- Water Use

- Mineral Resource Use

- Freshwater Ecotoxicity

From measuring fossil fuel consumption to quantifying GHGs emissions and assessing water consumption, each element provides a unique perspective on a product’s environmental impact.

Coming back to the example of fossil fuel consumption: this element delves into the energy required for raw material extraction, manufacturing, transportation, and disposal. By quantifying fossil fuel usage, businesses gain a clear picture of the carbon footprint associated with their products, enabling them to identify areas for improvement and implement sustainable practices.

Life Cycle Assessment Stages

1. Goal and Scope Definition:

The objectives and boundaries of the LCA are defined.

2. Life Cycle Inventory (LCI):

A detailed inventory of all inputs and outputs associated with the product being assessed is collected.

3. Life Cycle Impact Assessment (LCIA):

This phase assesses the significance of various environmental aspects, such as air and water pollution.

4. Interpretation:

The results of the LCA are analyzed and presented in a way that helps decision-makers draw conclusions and make informed decisions.

What is a Life Cycle Assessment for Packaging?

Packaging is a factor within the product’s life cycle, influencing the product’s environmental impact. A LCA that is specifically tailored to packaging is a strategic approach that analyses the complete journey of packaging materials, from inception to disposal. The assessment reaches beyond the traditional scope of evaluating the package-to-product ratio. It is a comprehensive analysis that considers the eco-friendliness of materials used, aiming to influence and reduce a product’s overall environmental footprint.

Packaging Life Cycle Assessment Examples

Many companies nowadays apply LCA analysis to determine which packaging is suitable for their businesses. Even with the same LCA results, companies may choose different packaging solutions depending on the business requirements.

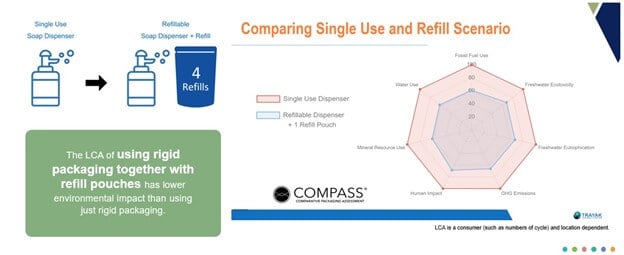

The chart below is an example from Trayak of conducting LCA analysis comparing single use rigid packaging and refillable rigid packaging with refill pouches. The LCA of using rigid packaging together with refill pouches has lower overall environmental impact than just rigid packaging.

Important Factors that Impact the Packaging LCA

1. Packaging-to-Product Ratio:

Measuring the ration of packaging to the actual product is an important aspect of LCA. Having the right balance is essential for reducing waste and optimizing resource usage.

2. Eco-Friendliness of Materials:

The environmental impact of packaging materials is a crucial factor. Evaluating eco-friendliness involves considering factors such as: biodegradability, recyclability, and the overall sustainability of the chosen materials.

3. Circular Economy Principles:

Efficient packaging design aligns with circular economy principles. This goes beyond material reduction and focuses on creating packaging that can be easily reused or recycled, adding to a closed-loop system.

4. Sustainable Practices:

Incorporating sustainable practices in packaging design is critical. This includes exploring innovative solutions, utilizing recycled materials and adopting eco-friendly technologies in the manufacturing process.

Criticism of the LCA

While LCA is a powerful tool, it does come along with some criticism. There are some concerns including defining proper system boundaries, trust in average data and the omission of social inferences. Addressing these concerns takes continuous refinement of LCA approaches and a commitment to clear transparency.

Leveraging LCA for Sustainability

In conclusion, Life Cycle Assessments are essential tools for evaluating the environmental impact of products and services. By going through the elements of LCA, we gain valuable insight into how our choices and actions affect the planet. As sustainability becomes a core value, understanding LCA data will be instrumental in achieving all our environmental goals. Contact us today to learn more about our sustainable packaging options.

References

“Blockchain Technology for Transparent Supply Chains.” Journal of Sustainable Business, vol. 15, no. 4, 2022.

“Circular Economy in Packaging: A Comprehensive Review.” Packaging Research, 2023.

“Cradle-to-Cradle Design Principles for Sustainable Products.” Journal of Sustainable Development, vol. 18, no. 2, 2022.

“Eco-Friendly Packaging Materials and Their Impact on the Environment.” Environmental Impact Assessment Journal, vol. 28, no. 4, 2023.

“Global Green Initiative Report 2023.” World Environmental Council.

“Internet of Things (IoT) Applications in Environmental Sustainability.” Technology and Sustainability Journal, vol. 12, no. 1, 2023.

“ISO 14040: Environmental Management – Life Cycle Assessment – Principles and Framework.”

“Life Cycle Assessment (LCA): A Comprehensive Guide.” Environmental Science and Technology Journal, vol. 25, no. 3, 2023.

“Life Cycle Assessment (LCA): why is it important?” ImPackting, 13 Feb. 2023.

“Sustainable Packaging Practices: A Guide for Businesses.” Packaging World Magazine, March 2023.