The demand for sustainable packaging has skyrocketed over the past decades and refill pouches are rapidly gaining traction as alternative to traditional containers. Whether you’re exploring ways to reduce plastic waste or enhance your brand’s environmental impact, this guide offers a comprehensive overview of refill pouch solutions covering their benefits, types, and practical applications to help you make informed decisions.

What are refill pouches?

Imagine this: flexible, liquid-friendly packages designed specifically to refill your permanent or semi-permanent bottles. They offer a convenient and eco-friendly alternative to traditional single-use bottles by allowing consumers to refill their existing containers, reducing plastic waste and environmental impact. Whether it’s shampoos, body washes, cosmetics or lotions, refill pouches come in two primary forms: single-use and multi-use.

Single-use Refill Pouches: A single-use refill pouch often features easy-tear openings, as reclosable functionality is unnecessary. These pouches typically hold less volume than a standard bottle, since many consumers refill before the bottle is completely empty. Without a spout, plastic usage can be reduced even further, making spoutless designs a more sustainable choice for single-use applications.

Multi-use Refill Pouches: Great for larger volumes, they have resealable opening like spouts with caps. These pouches enable multiple refills, optimizing convenience.

What are refill pouches made of?

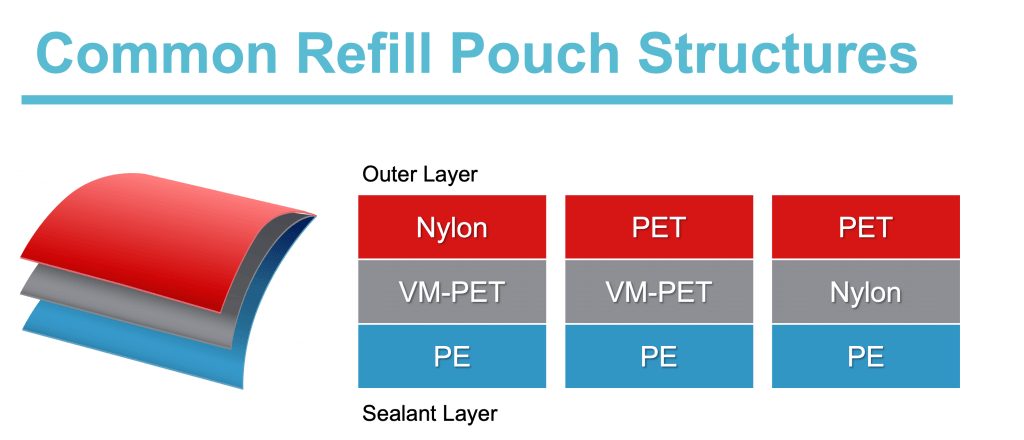

Most refill pouches are made from different types of plastic materials. Many liquid products need protection from moisture or odors, so these pouches are typically built with 2 to 3 layers (outer, barrier, and sealant layers). Each layer uses a different material to ensure the pouch is durable and performs well.

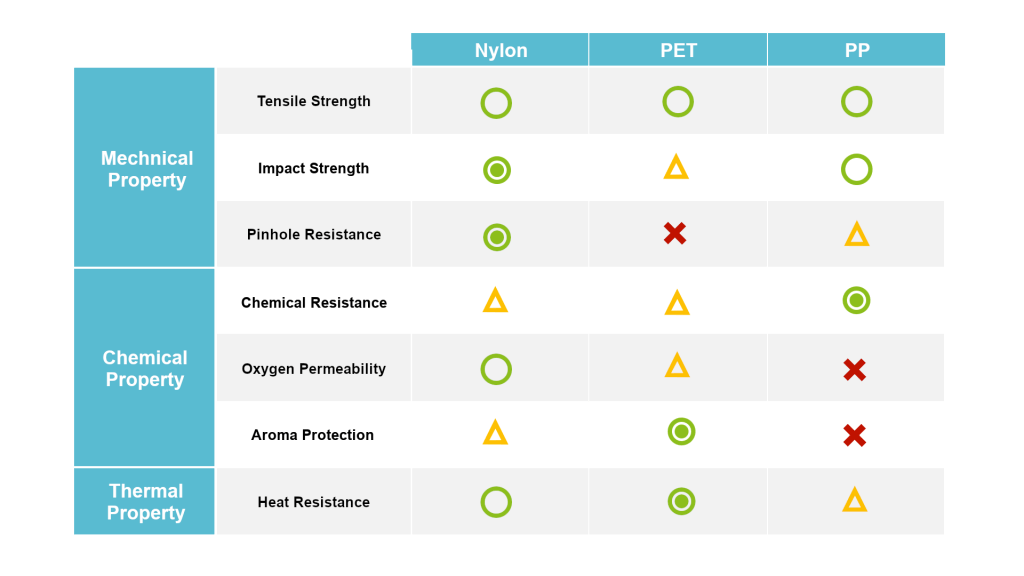

Outer layer: The outer layer plays a key role in making pouches durable. Nylon and PET are commonly used materials for this layer. Nylon is especially effective at preventing pinholes (tiny punctures that can lead to leaks). These pinholes often result from cracks, abrasions, or friction between pouches, and nylon helps reduce that risk. When pouches include a bottom gusset, nylon is often added to the bottom for extra strength.

PET is another popular choice because it’s widely available, cost-effective, and easy to process. It also offers excellent heat resistance, making it ideal for use as an outer layer in various applications.

Barrier layer: The barrier layer protects the contents of the pouch. It sits between the outer and sealant layers and can be made from different materials depending on the product’s needs. Two common options are nylon and vacuum metalized film (VM) or aluminum oxide (AlOx).

VM and AlOx offer strong protection against moisture, oxygen, aroma, flavor, and gas. VM also gives the pouch a metallic look, which can enhance design appeal. In contrast, AlOx is clear, making it a great choice for transparent pouches.

Sealant layer: The sealant layer keeps the pouch securely closed. The most common materials used for this layer are polyethylene (PE) and polypropylene (PP). In the U.S. market, PE is more widely used because it’s durable and readily available. PE comes in different forms based on density such as high-density (HDPE) and low-density (LDPE). For refill pouches, manufacturers often use linear low-density polyethylene (LLDPE) because it offers a good balance of flexibility and strength.

Pouch structure can be technical and complex. In addition to structure, chemical compatibility is critical for liquids. Having the wrong packaging materials can ruin the product. It is crucial to work with suppliers who are knowledgeable about materials and liquid chemical compatibility regarding the packaging.

Are refill pouches eco-friendly?

Refill pouches are among the most sustainable options available today. While many consumers equate sustainability with recyclability, true environmental impact goes far beyond that. One of the most effective tools to measure this is a Life Cycle Assessment (LCA), which evaluates a package’s footprint from raw material sourcing to end-of-life disposal.

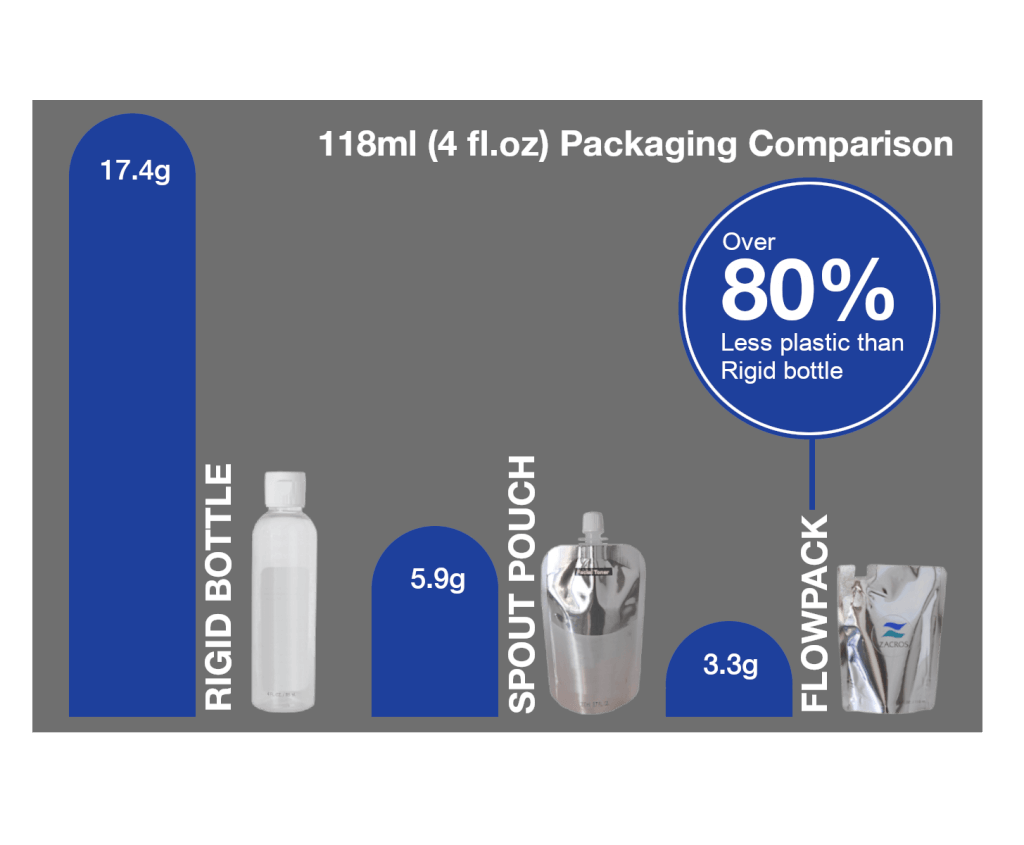

According to LCA data, refill pouches use up to 80–90% less plastic than rigid bottles and generate 70% fewer greenhouse gas (GHG) emissions during production. They also require far less fuel for transportation. One truckload of empty pouches can replace 7 truckloads of empty bottles, dramatically reducing carbon emissions.

Additionally, flexible pouches can be modified to meet various levels of sustainability needs, such as lightweighting designs to reduce resource use or using monomaterial structure for improved recyclability. Their customizable structure makes them ideal for brands aiming to balance performance, cost, and environmental goals.

Alison Keane, Esq., IOM, CAE

Former President & CEO, Flexible Packaging Association

“The U.S. Environmental Protection Agency’s long-standing goals for waste management start with source reduction and reuse; followed by recycling and composting, energy recovery, and then disposal as the least preferred method. Refillable systems, like refill pouches for reusable containers and refillable pouches, prioritize the highest priority of source reduction and reuse by avoiding the need for virgin production, including the related carbon footprint when compared to manufacturing of new packaging and products and the recycling of them. In addition, it shifts consumer behavior to more circular thinking and action without the loss of convenience. It’s a win-win for consumers and the environment!”

Are refill pouches recyclable?

Recyclability has long been a challenge for flexible pouches. Most traditional pouches are made from multiple laminated layers of different materials, which makes them difficult to recycle. This issue is compounded by the limited recycling infrastructure available in many regions. Programs like TerraCycle and Pact Collective offer solutions for hard-to-recycle packaging, but these solutions do not create true circularity.

While monomaterial, recycle-ready pouches such as ZACROS’s MONOSOLUTIONS® Flowpack series are becoming more common, their recyclability still depends heavily on the type of liquid and the capabilities of local recycling facilities. There are store drop-off programs for flexible packaging, but most liquid products do not qualify for these programs due to contamination risks.

Even when packaging is technically recyclable, consumer behavior presents another hurdle. Studies show that while 94% of Americans support recycling, only about 35% actually recycle, and many do so incorrectly, contaminating entire batches. This “intention-action gap” means that even recyclable packaging often ends up in landfills.

What are the benefits of refill pouches?

Refill pouches help strengthen the relationship between brands and consumers—what we call the Refill Pouch Benefit Cycle.

For brands, refill pouches lower packaging costs, which can lead to more affordable pricing for consumers. This is especially important for millennial shoppers, who often prioritize price when making purchasing decisions. For consumers, refill pouches are user-friendly and efficient. They’re easier to empty than rigid bottles, which means less product is wasted. This makes them both cost-effective and convenient.

These benefits encourage repeat purchases, helping brands improve customer loyalty and market positioning. At the same time, refill pouches support sustainability goals by reducing plastic use and offering more eco-friendly packaging options. In short, refill pouches create a win-win for brands and consumers.

Luci Petlack, PhD

Sustainability + Lifestyle Writer, Luci’s Morsels

“As a mother and homeowner, we’re always trying to live more sustainably while keeping everything going in the right direction. Refill pouches save us from having to make more trips to the store or have more deliveries (cutting back on emissions everywhere). Refill pouches also require drastically less water and energy to produce than the typical bottles they’re replacing, which requires no extra work on our part. Finally, they’re easy to store. Our cleaning product storage is more organized, consuming less space – taking up less and less room as we use the products.”

Additional FAQs

What types of products are best suited for refill pouches?

Refill pouches are ideal for liquid and semi-liquid products. Common applications include:

-

Personal care products

Shampoo, conditioner, body wash, lotion, and facial cleansers for consumers and professional applications

-

Cosmetics

Serum, facial cream, and toner

-

Home care products

Dish soap, laundry detergent, surface cleaners, and hand soap

-

Pet care

Liquid pet shampoos and grooming solutions

Do refill pouches affect product shelf life?

Refill pouches can maintain or even extend product shelf life when designed with the right materials. The barrier layer in the pouch protects contents from moisture, oxygen, and light, which are key factors in product degradation.

However, chemical compatibility between the pouch materials and the product is just as important. Certain ingredients, especially in cosmetics, can interact with the packaging, leading to delamination or a loss of product efficacy over time. That is why it is critical to select materials that are chemically stable with the specific formulation inside.

What should brands consider when transitioning from rigid to flexible packaging?

When switching from rigid containers to flexible packaging like refill pouches, brands should evaluate several important factors:

-

Product Compatibility

Ensure the pouch materials are chemically compatible with the product contents to prevent degradation, discoloration, or leaks.

-

Barrier Requirements

Choose materials that offer the right protection against moisture, oxygen, aroma, and light based on the product’s sensitivity.

-

Durability and Seal Integrity

Liquids are heavier than dry goods, so the pouch must be strong enough to prevent punctures and maintain a secure seal.

-

Sustainability Goals

Decide whether to use monomaterial structures for recyclability or lightweight multilayer designs to reduce resource use.

-

Product Filling

The filling equipment for flexible pouches is different from that used for rigid bottles. ZACROS has many pouch filler partners we can refer you to.

-

Print Appearance

Be aware that even if the same color is used, print results may vary depending on the material type. Different substrates absorb ink differently, which can affect color consistency across packaging formats.

-

Regulatory and Labeling Compliance

Ensure the packaging meets safety, labeling, and recycling regulations in your target markets.

Collaborating with experienced suppliers can help brands navigate these considerations and ensure a smooth transition to flexible packaging.

How do you fill refill pouches?

Filling refill pouches requires specialized equipment and processes tailored to the pouch design and product type.

-

Form and Fill

Horizontal or vertical form-fill-seal (FFS) machines are commonly used. These machines form the pouch, fill it with product, and seal it in one continuous process.

-

Fill from Spout

For pre-made pouches with spouts, filling is typically done through the spout using a nozzle filler, followed by capping.

-

Fill from Top

Spoutless pouches are often filled through the top opening and sealed using heat or ultrasonic sealing. Because the pouch needs to be sealed after filling, a small headspace is required to ensure proper sealing and avoid leaks.

The filling method depends on the pouch structure, product viscosity, and production volume. Collaborating with equipment manufacturers and packaging experts ensures optimal performance and product integrity.

What is the difference between monomaterial and multilayer refill pouches?

The key difference lies in the number and type of materials used:

-

- Multilayer refill pouches combine different materials (e.g., nylon, PET, aluminum oxide) to achieve durability, barrier protection, and heat resistance. However, these layers make recycling difficult because they must be separated.

- Monomaterial refill pouches are made from a single type of plastic (like polyethylene), which simplifies recycling process. These pouches are designed to balance performance and sustainability, though they may face limitations in barrier strength or durability depending on the product.

Monomaterial pouches are used for recycle-ready designs, especially in markets focused on circular packaging solutions.

Refill Pouches for Future Sustainable Packaging

Refill pouches are sustainable packaging solution gaining momentum in the U.S. market. They have been widely adopted in many countries like Japan, where refill culture is well established. For example, over the past 20 years, Japan has seen demand for personal and home care products double, yet packaging material consumption has dropped by 42%, thanks in large part to refill pouches.

As one of Japan’s leading refill pouch manufacturers, ZACROS supports brands in transitioning from rigid to flexible packaging. Through extensive testing and innovation, we have developed materials tailored to a wide range of product types, helping brands reduce waste while maintaining quality and performance.

If you are exploring sustainable packaging options, refill pouches offer a proven path forward. Contact us to learn how ZACROS can support your brand’s sustainability goals.

References

Japan Soap and Detergent Association. “Sustainable Plastic Use.” Japan Soap and Detergent Association, https://jsda.org/e/k_sus_plasticuse.html. Accessed 2023.

ProSource. “Principle of Flexible Packaging Performance Characteristics.” ProSource, https://www.prosource.org/article/22210174/principle-flexible-packaging-performance-characteristics. Accessed 2023.