PCR plastic packaging is a sustainable packaging solution currently gaining traction in the pursuit of limiting the environmental impacts of product waste. Many global leading brand owners have announced their sustainability commitments to incorporate PCR plastics by 2025-2030. Before adopting this solution, you should consider the challenges you might face with PCR plastics. PCR is not a perfect solution, and it comes with its unique advantages and disadvantages. First, let us discuss the basics.

What is PCR plastic?

PCR stands for Post-Consumer Recycled. Some people use PCR as Post-Consumer Resin. PCR plastics are end products of the recycling process from used plastics. There are many types of plastics in the market, but the most common PCR materials are high-density polyethylene (HDPE) and polyethylene terephthalate (PET). The amount of polypropylene (PP) collected through recycling is less than HDPE and PET, making it less available as a PCR format. However, there are growing demands for PP PCR plastics along with HDPE and PET. The benefits of using PCR, such as reduction in total carbon footprints, and reduction of waste and use of raw materials, are already well known. However, it is vital to recognize the challenges of using PCR to make the right decisions. To understand the challenges associated with PCR, first, we must understand how it is made.

The most popularly used plastic recycling system, known as mechanical recycling, requires various steps, including sorting, cleaning, shredding, melting, and remolding. After the mechanical recycling process, used plastics become PCR resin used to manufacture plastic products once again.

Consideration 1: PCR Material Quality – Degradation

Plastics are typically composed of polymers. The polymers have long-chain structures with various elements such as carbon, hydrogen, oxygen, and nitrogen. During the recycling process, the polymer chains break down, resulting in degradation. This is why it is challenging to create packaging with 100% PCR with the same durability and performance as packaging manufactured from virgin resin. Most plastic can only be recycled a few times before it becomes unusable. There has been tremendous innovation around PCR, making it possible to develop 100% PCR packaging with good performance, such as the packaging used for Colgate-Palmolive dish soap. However, it is still one of the main hurdles associated with PCR.

Consideration 2: PCR Material Quality – Impurity

In addition, not all recyclable plastics are recycled—quality matters. Plastics have not only different chemical and physical properties but also different applications. For these reasons, plastics that are collected contain various materials, sizes, shapes, and colors. Even though plastics go through an intensive sorting process, PCR resin can still result in some impurities. Therefore, recycled plastics generally must have good quality to be accepted for reprocessing. On top of the challenge of finding a steady supply of PCR, brand owners who wish to use such materials are also faced with ensuring that the supply they have found is of adequate quality.

Consideration 3: PCR Material Supply

Lastly, as mentioned above, the supply of PCR plastics cannot support the growing PCR plastic demand. According to Waste Management, 25% of materials that consumers place in recycling bins do not get recycled due to contamination. While many consumers understand the importance of recycling, there is a general lack of understanding on how to recycle products.

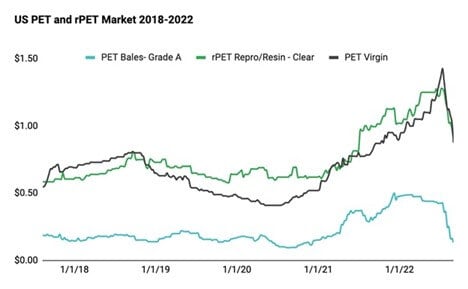

The chart below details how the US PCR markets have changed over the past five years, polyethylene or PET, and recycled PET or rPET.

In 2018, China stopped importing about two billion tons of plastic trash each year. Quickly, the world realized the impact and size of our global waste issue. From 2019 to 2021, governments implemented policies to reduce virgin plastic and brands committed to circularity goals. It is a good start but still detrimental to both supply and demand.

Current / Futuristic PCR Market:

Supply

- The current supply of PCR used in packaging is not projected to meet the demands that we have over the next few years.

- Waste recycling, recovery and collection are becoming more economically attractive. Large companies like, KW Plastics invested and expanded in new capacity, increasing supply volume and quality.

- Packaging norms are changing towards sustainable recyclable designs, ultimately increasing higher quality “circular” supply.

Demand

- Buyers and sellers now have a new opportunity with these new digital marketplaces to make trading more feasible.

- PCR packaging helps reduce the demand for raw materials and decreases the amount of plastic sent to landfills.

- PCR demands continue to increase as oil becomes more expensive and generally not wanted.

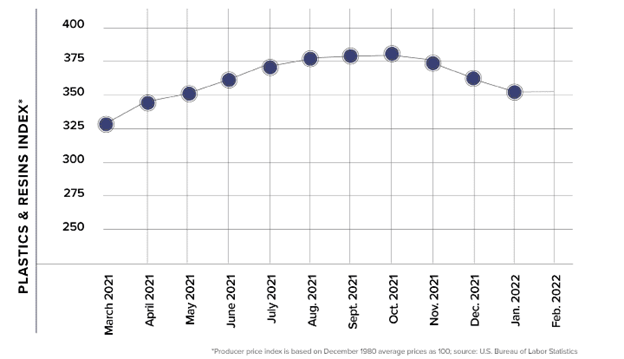

This graph below showcases the plastics and resins index have been declining since October 2021. This is caused by the inflation directed demand of the supply chain.

Summary

In conclusion, PCR plastic is a great sustainable option. It is essential to be aware of the challenges and use PCR as one of the options to achieve sustainability goals. ZACROS has been in the flexible liquid packaging market for over 50 years. We have experience and knowledge about packaging as well as materials. We think beyond the packaging with our innovations. Contact us to learn more.

References

“Misalignment between PCR supply and demand.” Recycling Today.

“The Economic Case for Recycled Plastics Is Improving.” IndustryWeek.

“What Is PCR Plastic? The Pros and Cons of PCR Packaging.” thecarycompany.com.