The demand for sustainable packaging has skyrocketed over the past decades and refill pouches are emerging as a leading solution in the realm of eco-friendly packaging. If you’re considering incorporating refill pouches into your product lineup, this guide will provide you with a comprehensive overview of everything you need to know.

What are refill pouches?

Imagine this: flexible, liquid-friendly packages designed specifically to refill your permanent or semi-permanent bottles. They offer a convenient and eco-friendly alternative to traditional single-use bottles by allowing consumers to refill their existing containers, reducing plastic waste and environmental impact. Whether it’s shampoos, body washes, cosmetics or lotions, refill pouches come in two primary forms: single-use and multi-use.

Single-use Refill Pouches: Featuring easy-tear openings, these pouches are great for quick refills, often with a volume slightly smaller than the bottle’s capacity. They are convenient and allow users to refill before the bottle empties completely.

Multi-use Refill Pouches: Great for larger volumes, they have resealable opening like spouts with caps. These pouches enable multiple refills, optimizing convenience.

What are refill pouches made of?

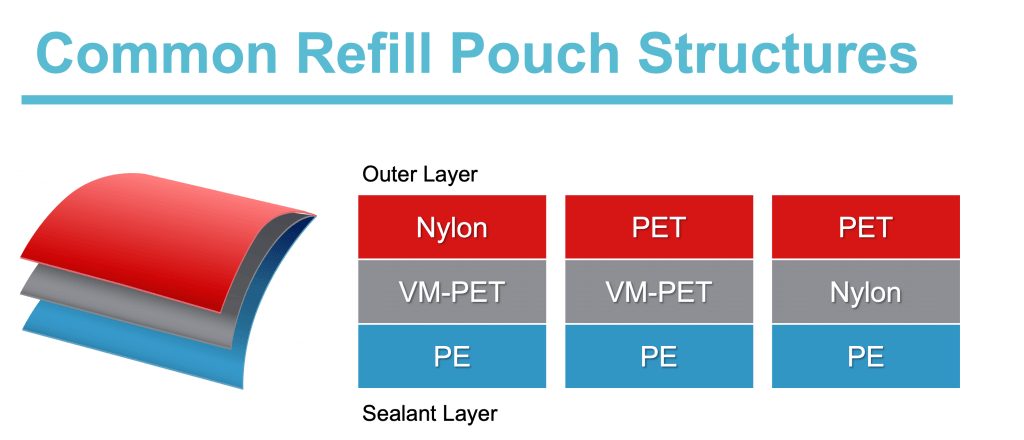

Taking a closer look, refill pouches pride themselves with complex construction typically involving multiple layers tailored to maintain liquid reliability. Below is a typical breakdown:

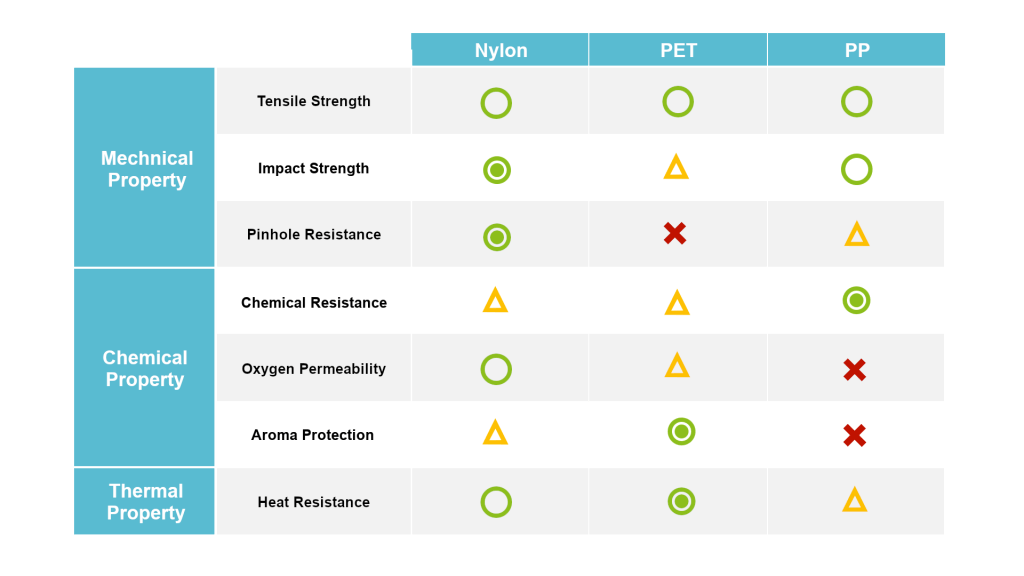

Outer layer: Nylon and PET reinforce durability and prevent common issues like pinholes, ensuring your pouches are long lasting. Nylon and PET are flexible materials, which allow them to conform to the shape of its contents and surroundings without easily breaking. This flexibility helps prevent stress points that could lead to these pinholes.

Barrier layer: Materials like aluminum vacuum metalized film (VM), aluminum oxide (AIOX), and ethylene-vinyl alcohol copolymer (EVOH) offer exceptional moisture, aroma and gas barriers, with VM lending a metallic sheen for design elegance.

Sealant layer: Polyethylene (PE) and Polypropylene (PP) are the leaders here by providing vigorous sealing and durability, often utilizing variations like LLDPE.

Pouch structure can be technical and complex. In addition to structure, chemical compatibility is critical for liquids. Having the wrong packaging materials can ruin the product. It is crucial to work with suppliers who are knowledgeable about materials and liquid chemical compatibility regarding the packaging.

Are refill pouches eco-friendly?

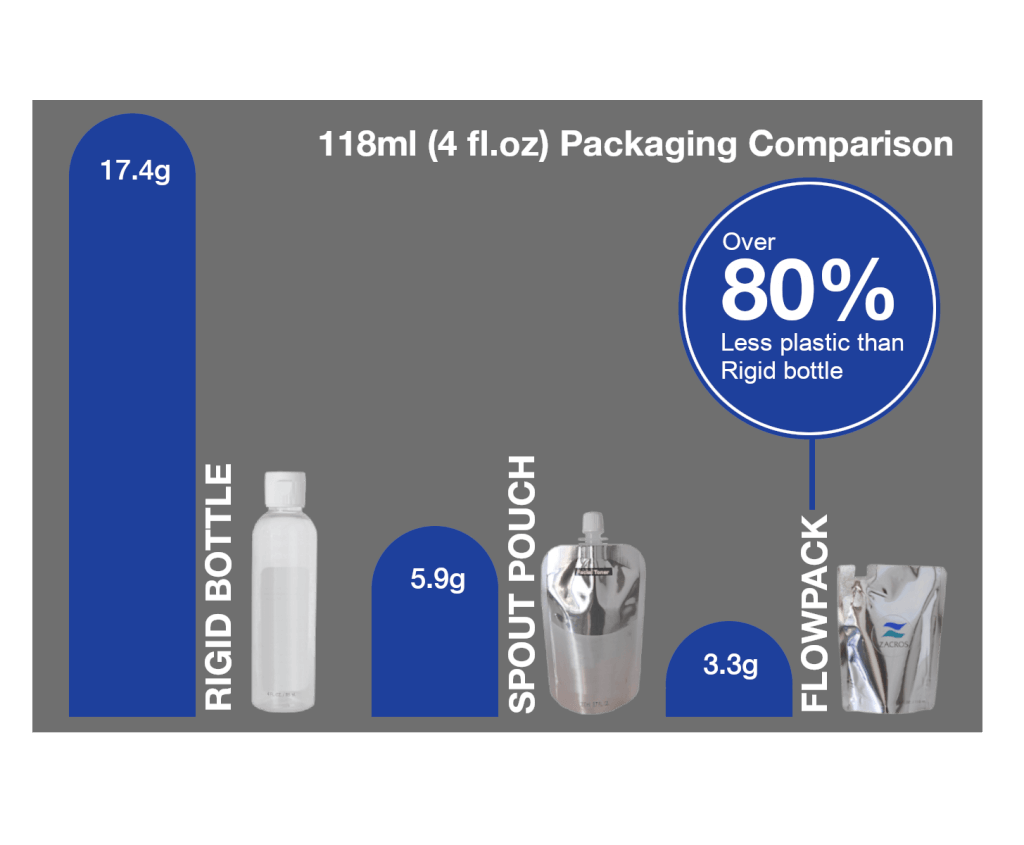

It’s not just about recyclability; refill pouches significantly reduce the carbon footprint compared to rigid bottles, slashing plastic usage by a staggering 80-90%. Even EPA lists “Source Reduction & Reuse” as the most preferred waste management method followed by “Recycling / Composting”.

Transportation has one of the biggest environmental impacts among the products’ life cycle. It is said that flexible pouches only need one truckload while rigid bottles need 10-15 truckloads when empty. With this in mind, we believe that refill pouches are better for the environment overall. It is not only lightweight but also durable and easily customizable.

Alison Keane, Esq., IOM, CAE

Former President & CEO, Flexible Packaging Association

“The U.S. Environmental Protection Agency’s long-standing goals for waste management start with source reduction and reuse; followed by recycling and composting, energy recovery, and then disposal as the least preferred method. Refillable systems, like refill pouches for reusable containers and refillable pouches, prioritize the highest priority of source reduction and reuse by avoiding the need for virgin production, including the related carbon footprint when compared to manufacturing of new packaging and products and the recycling of them. In addition, it shifts consumer behavior to more circular thinking and action without the loss of convenience. It’s a win-win for consumers and the environment!”

Are refill pouches recyclable?

Recyclability has always been a struggle for flexible pouches. Typical multilayered flexible pouches are harder to recycle because they combine different materials together during the lamination process. This has additionally been compounded by the lack of recycling infrastructure. However, due to the number of materials used, flexible pouches will reduce the overall amount of plastic put into landfills despite having low recyclability.

This is not to say that it is impossible to have a fully recyclable flexible pouch; there are indeed some recyclable flexible pouches in the market. The main issue for a recyclable flexible pouch is to sustain content using only one material. The traditional flexible pouch uses multi-materials because each material contains different functionalities, such as nylon for higher durability and PET for heat resistance. Improper sealing can easily lead to defective seals resulting in a poor-quality pouch. Since liquids weigh more than dry products, and so, it is necessary to have higher durability to support the contents. Although there are many obstacles to face, we are starting to see monomaterial liquid flexible pouches coming out to the market, including ZACROS MONOSOLUTIONS® Flowpack. With refill pouches, you can achieve various levels of sustainability depending on your business needs.

What are the benefits of refill pouches?

Refill pouches aren’t just about sustainability; they establish stronger brand-consumer relationships. Lower packaging costs change to consumer-friendly pricing, while the ease of cost-effectiveness drive repeat purchases. Brands benefit from enhanced sustainability credentials, aligning with consumer preferences for eco-conscious products.

In order for brands to be successful with refill pouches, many surveys indicated that labeling packaging with educational information such as plastic reductions to consumers is critical.

Luci Petlack, PhD

Sustainability + Lifestyle Writer, Luci’s Morsels

“As a mother and homeowner, we’re always trying to live more sustainably while keeping everything going in the right direction. Refill pouches save us from having to make more trips to the store or have more deliveries (cutting back on emissions everywhere). Refill pouches also require drastically less water and energy to produce than the typical bottles they’re replacing, which requires no extra work on our part. Finally, they’re easy to store. Our cleaning product storage is more organized, consuming less space – taking up less and less room as we use the products.”

Refill Pouches for Future Sustainable Packaging

Refill pouches are great sustainable packaging solutions. They are relatively new to the US market but well-established in many countries, especially in Asia. For example, in Japan, the demand for personal and home care products has doubled in the past 20 years. Conversely, however, the material consumption of plastic packaging has decreased by 42%. With this, the Japanese market has proved that refill pouches improve sustainability. ZACROS was one of Japan’s leading refill pouch manufacturers that established a “refill culture” in Japan. We manufacture over 500 million refill pouches every year. ZACROS had countless experiments to figure out which packaging materials are adequate for different types of contents. Contact us for more information.

References

Japan Soap and Detergent Association. “Sustainable Plastic Use.” Japan Soap and Detergent Association, https://jsda.org/e/k_sus_plasticuse.html. Accessed 2023.

ProSource. “Principle of Flexible Packaging Performance Characteristics.” ProSource, https://www.prosource.org/article/22210174/principle-flexible-packaging-performance-characteristics. Accessed 2023.