Packaging plays an essential role in cosmetics. Even though flexible packaging is growing in the cosmetics industry, most beauty products still use rigid packaging. Sometimes, brands focus too much on designs and overlook the importance of preservation when it comes down to flexible packaging. It is essential to understand that flexible packaging preserves products differently than rigid packaging. In this blog, we will go over why preservation is critical when you switch to flexible packaging.

Purposes of Primary Packaging

First and foremost, what is the purpose of primary packaging? Cosmetics packaging serves several purposes, including design, protection, and preservation. Packaging design is essential in differentiating a product from competitors, communicating brand messages, and enticing consumers. In addition, protecting the product from external factors such as physical damage and contamination is extremely important. When dealing with liquid products, it is critical to have a proper closure to prevent spillage. Proper packaging helps maintain the integrity and safety of the cosmetics throughout their shelf life, ensuring that they reach consumers in optimal condition. Lastly, packaging plays a vital role in preserving the quality and stability of the product formulation. It helps prevent ingredients from degrading, separating, or becoming less effective over time. With flexible packaging, barrier layers are typically applied to protect products from external factors. However, internal factors are often neglected when it comes to preservation. What does that mean? Let’s dive into the background of preservation.

Permeability Affects Packaging Preservation

Preservation is strongly related to the permeability of packaging materials. Permeability measures a material’s ability to transmit liquids, gases, and vapors through a material. Some materials have higher permeability for specific components compared to others. For example, glass containers have a much lower permeability of a wide range of components, such as oxygen, moisture, and light, than other types of packaging. That is why glass is considered the most stable packaging type. In packaging, two elements can impact the preservation of products: external and internal elements.

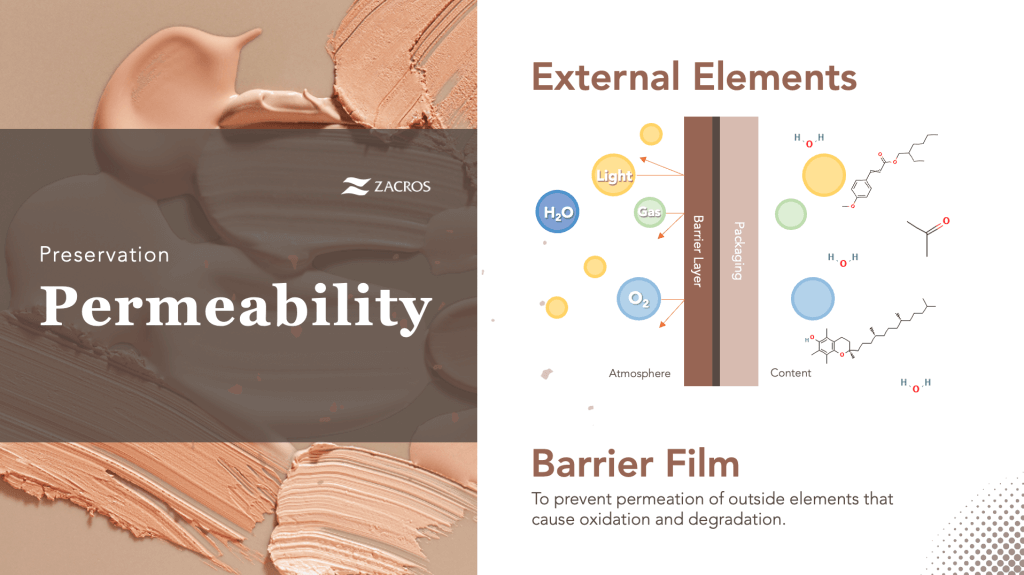

1). Permeability of External Elements

External elements such as oxygen, moisture, gas, and light are one of the elements that impact the preservation of products. Those external elements can lead to oxidation, discoloration, and degradation of the packaged product.

Solution: External Element Interactions with Packaging

Barrier layers are commonly used in flexible packaging to prevent the permeation of external elements. These barrier layers act as a protective sheet, helping maintain the product’s quality and shelf-life. Common materials used as barrier layers in flexible packaging include metalized films, aluminum foil, silicon oxide (SiOx), and ethylene vinyl alcohol (EVOH).

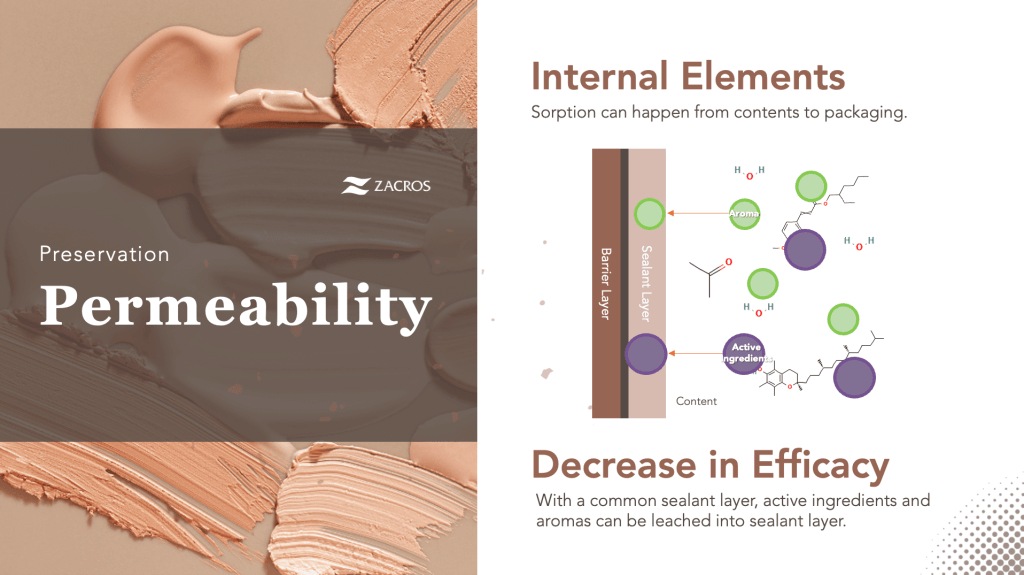

2). Permeability of Internal Elements

Barrier layers are excellent ways to prevent contact with external elements. However, barrier layers don’t necessarily prevent the interaction between products and packaging. Cosmetic products often contain various ingredients such as oils, fragrances, preservatives, and unique active ingredients. Some chemicals in cosmetics can potentially interact with the sealant layer, leading to leaching and reducing the efficacy of the products. This is particularly relevant in cases where the chemicals used in the cosmetics formulation are sensitive or can migrate through the packaging materials. Chemicals can also attack adhesives between films, causing delamination which could lead to defective packaging.

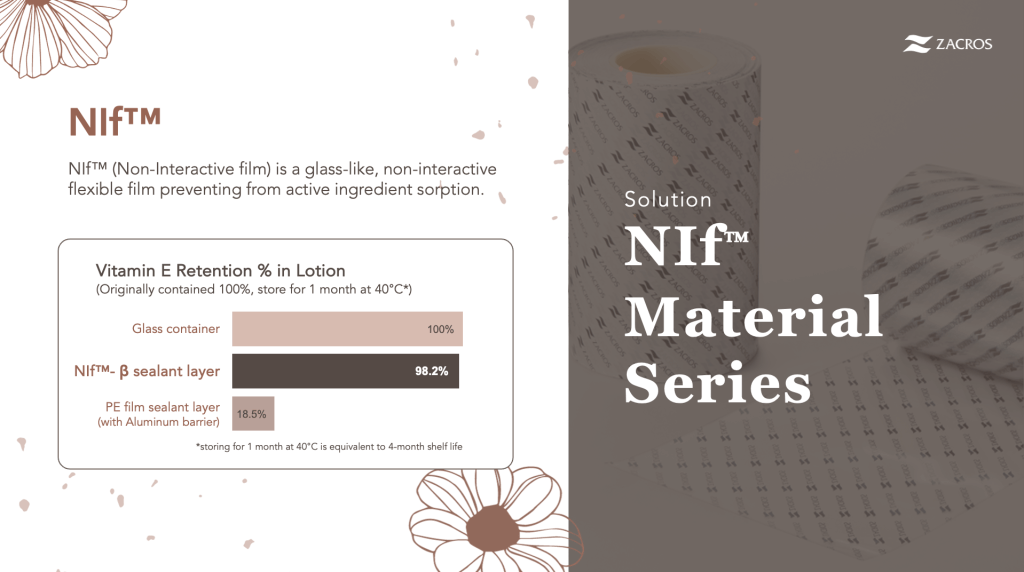

Solution: Internal Element Interactions with Packaging

To mitigate these issues, manufacturers of cosmetics and flexible packaging need to carefully select compatible packaging materials and formulations. ZACROS offers a glass-like performance sealant film called NIf™ material to reduce the interaction between products and packaging. NIf™ is proven to show high retention rates for many commonly used cosmetics’ active ingredients. Testing and evaluation should be conducted to ensure that the packaging maintains the quality and efficacy of the cosmetic product throughout its shelf life.

Flexible Packaging and Preservation Key Take Aways

- Look beyond packaging designs

In the competitive cosmetics industry, brands tend to prioritize packaging design over preservation and functionality. Sample sachets are one type of packaging that tends to be overlooked, even though samples play an important role in representing brands. Some brands may prioritize cost-cutting measures and adopt cheaper packaging solutions that may not offer adequate protection and preservation for the product. While attractive packaging can certainly enhance the appeal of a product, neglecting preservation can have negative consequences on product quality and brand reputation.

- Test packaging with products

Testing cosmetics with packaging is crucial to ensure the packaging protects and preserves the products. This testing is essential to guarantee products’ safety, efficacy, and quality throughout their shelf life. Different packaging types, such as glass, aluminum, and plastic, have pros and cons. Packaging materials should be compatible with the formulation to avoid interactions that could alter the product’s properties or stability. Testing helps manufacturers identify potential issues, optimize packaging designs, and ensure that cosmetics products meet the highest standards of safety, quality, and performance for consumers.

- Find suitable packaging partners

In some cases, brands lack awareness or understanding of the importance of packaging preservation. They may not have the necessary expertise to evaluate and implement effective strategies. Partnering with reliable and experienced packaging suppliers is vital to finding the right packaging solutions for your products. Suppliers specializing in the cosmetics industry have knowledge and experience in understanding cosmetic products’ unique requirements and challenges. They can provide valuable insights and recommendations on the most suitable packaging that aligns with your product specifications and branding objectives. Nowadays, it is easy to purchase packaging without interacting with suppliers. However, partnering with suitable packaging suppliers is essential for ensuring the success, quality, and competitiveness of your products.

Beauty, Home & Personal Care Liquid Flexible Packaging Expert

Are you seeking an experienced liquid flexible packaging supplier for your cosmetics products? ZACROS has provided quality flexible packaging for beauty, home & personal care liquid products for over 25 years. We have an intensive chemical compatibility database to find you with a suitable packaging solution. ZACROS AMERICA also partners with fillers across the US to support switching from rigid to flexible packaging. Contact us today to learn more.