Top 8 Frequently Asked Questions About LCA for Packaging

As sustainability becomes a business imperative, brand owners are increasingly expected to make packaging decisions that are not only functional but also environmentally responsible. Yet, many are unfamiliar with the tools that can guide these choices. In this blog, we explore the core elements of Life Cycle Assessment (LCA), highlighting its importance, key packaging comparisons, and how it empowers decision-makers to contribute to a more sustainable packaging future.

1. What is Life Cycle Assessment (LCA) and why should you care?

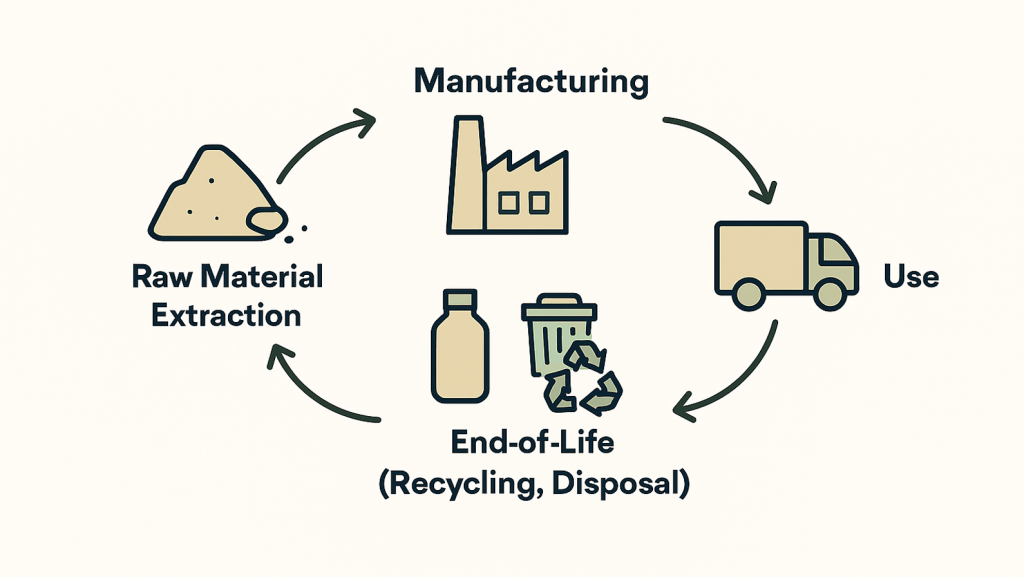

LCA is a scientific method used to evaluate the environmental impact of a packaging product across its entire life cycle from raw material extraction, manufacturing, and transportation to usage and end-of-life disposal.

It helps you understand the true environmental footprint of your packaging and avoid greenwashing by supporting sustainability claims with credible data.

2. What are the Main Stages of LCA for Packaging?

LCA is structured according to ISO 14040/14044 standards into four phases.

- Goal and Scope Definition – define objectives and boundaries of the LCA

- Life Cycle Inventory (LCI) – collect data on all inputs and outputs associated with the product

- Life Cycle Impact Assessment (LCIA) – evaluate the significance of various environmental aspects, such as air and water pollution

- Interpretation – draw conclusions from the analysis that helps decision-makers make informed decisions

3. What is the difference between LCA and Carbon Footprint Analysis?

LCA and Carbon Footprint Analysis are both tools used to evaluate environmental impact, but they differ in scope and depth. While Carbon Footprint Analysis focuses specifically on measuring the total greenhouse gas emissions associated with a product or activity, LCA is a comprehensive method that assesses multiple environmental impacts across all stages of a product’s life cycle, from raw material extraction to disposal. Carbon footprint is one component of LCA, but LCA provides a broader and more holistic view of sustainability.

4. What are the key elements of LCA for packaging

LCA breaks down environmental impact into measurable categories. Here are some examples.

- Greenhouse Gas (GHG) Emissions

- Fossil Fuel Use

- Water Use

- Mineral Resource Use

- Freshwater Ecotoxicity

These metrics empower brand owners to compare packaging formats (e.g., rigid vs. flexible) and choose options that minimize environmental harm.

5. How LCA helps you make smarter packaging choices

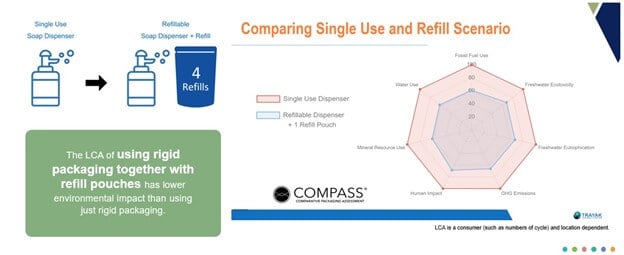

In packaging, end-of-life disposal is often emphasized, but a holistic perspective is essential for making informed decisions. LCA is especially useful when evaluating trade-offs between packaging formats.

For example:

- Flexible pouches use significantly less water during production compared to HDPE plastic bottles

- Plastic bottles typically have a lower carbon footprint than glass due to their lighter weight and reduced transportation emissions, even though glass being more recyclable

- Flexible pouches often outperform carton boxes in overall environmental impact, particularly in material efficiency and lower greenhouse gas emissions during production and disposal

By using LCA, you can quantify these benefits and communicate them credibly to stakeholders and consumers. Even with the same LCA results, companies may choose different packaging solutions depending on the business requirements.

Example from Trayak of conducting LCA analysis comparing single use rigid packaging and refillable rigid packaging with refill pouches

6. How are reused or recycled materials handled in LCA?

Reused and recycled materials are accounted for by adjusting the environmental impact based on their origin and end-of-life fate. Recycled content typically reduces the impact of raw material extraction, while reuse extends the product’s life and spreads its environmental burden over multiple uses. However, modeling these benefits accurately depends on assumptions about collection rates, contamination, and future recycling potential, which can vary by region and system.

7. What are the limitations and challenges of LCA?

While LCA is a powerful tool, it does come with limitations. Results can vary depending on the assumptions, data quality, and system boundaries, making comparisons between packaging formats challenging. Additionally, LCA typically focuses on environmental metrics and may overlook social or economic factors. Despite these challenges, LCA remains one of the most credible methods for guiding sustainable packaging decisions when used transparently and consistently.

8. Who publishes LCA results?

LCA results are often published through sustainability reports or academic journals. However, many companies keep results internal due to competitive concerns and the complexity of methodologies. Reliable data sources include commercial LCA databases, government and academic repositories, and industry-specific databases.

Leveraging LCA for Sustainability

LCA is an essential tool for businesses striving to reduce environmental impact and align with sustainability goals. While LCA has its challenges, its insights are invaluable for building packaging strategies that are both responsible and resilient. Whether you’re just starting or refining your sustainability roadmap, LCA is a key step toward meaningful impact.